Help File Topic Links

Zeroing the FP1 The FP1 needs to be zeroed often, this shows you how

Sleep, waking the FP1 The sleep feature will save your battery if you forget to turn off your FP1

PS3 pressure sensor 3 Optional pressure sensor 3 (PS3) information

Velocity Probe A velocity probe can be used on the standard FP1, or with optional PS3

FP1 to PC Connection Connecting the FP1 to your PC

FPcom Software FPcom is the Windows PC software that operates your FP1

Status Bar The FPcom status bar shows you important FP1 settings.

Data Capture There are several ways to capture data

FPconfig file Reassign the cells that data will be sent to with a config file

FP1 general information The FP1 is the electronic box that measures the flow rates in your flow bench

FP1 data entry How to enter and change FP1 settings and operating parameters

FP1 to Bench connections Information on connecting FP1 to flow bench

Flow Performance system connection

Flow Bench Operation Flow bench operating procedure

Flow Bench Calibration Information on calibrating your flow bench

PWM Port, Aux3 The PWM port (Aux3) controls a PWM motor for automatic test pressure

FP1 Command Summary A brief listing of commands and their functions for quick reference

FP1 command list Listing of all FP1 data and parameter commands

____________________________________________________

Zeroing the FP1

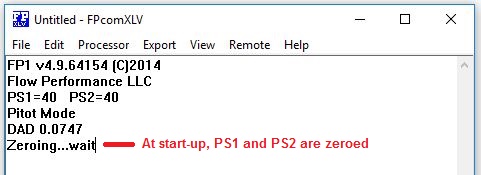

The pressure sensors of

the FP1 will drift with time and temperature. They need to be re-zeroed from

time

to time, and especially soon after start-up or before

doing any calibration or flow testing. The FP1 provides the user

the ability to view the zero state of the sensors,

and to easily re-zero the sensors with the touch of a button.

The sensors must be zeroed only when absolutely no pressure is being applied

to

them. Do not move the

pressure tubing or velocity probe or FP1 while zeroing.

Make sure your flow

bench is completely powered down, and that the hoses connecting your bench

to the FP1 or to a velocity probe are not moved

during the zeroing process.

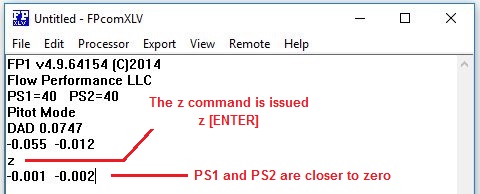

Press the z (lower

case) key, then RETURN or ENTER.

The FP1 should report

“Zeroing…wait” for about 2-5 seconds.

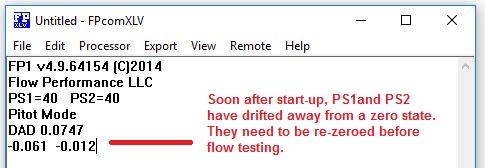

The FP1 should then

continue reporting pressure sensor readings that should be closer to .000

In all modes of

operation, PS1 and PS2 assume a .001 resolution manometer mode when no pressure

is

Applied (high pressure

sensors may display a .01” resolution). PS1 is represented in column one of the

readout,

and PS2 in column two. This provides the user a view

of the zero state of the sensors when there is no pressure applied.

Before

doing any flow testing, it is a

good practice to run your pressure up to the intended test pressure for a

moment,

then to release the pressure to zero pressure, and

then zero the processor.

Bounce: The

sensor readings will tend to “bounce” and a steady zero state of .000 should

not be expected.

The amount of bounce

depends greatly on the sample duration setting (s, or S) and the

range of the sensor

installed into your FP1. Typically, for a sample duration

of 50 (maximum, 20 in earlier model FP1s), the bounce

is about .003”wc for 40”wc sensors and .01”wc for

higher pressure sensors.

Hard

Zero (Z) If the pressure on PS1 has drifted higher than

.1”wc (or greater than the value of p on later

versions), the FP1 will go into System-On Calibration if

you try to zero the FP1. For this reason, Hard

Zeroing will cause the

FP1 to zero the sensors no matter what the pressure on PS1.

To cause a Hard Zero,

press the Z (UC) key, then ENTER or RETURN.

Sensor

drift

The sensors will drift

dramatically at start-up for about 30 seconds, then

continue to slowly drift for several

minutes. This is normal, as the sensors are adjusting to

the heat created within the electronic circuits of the

FP1.

Temperature change is the

main reason for sensor drift. If the ambient temperature is changing, the

sensors

will tend to drift at a higher rate. To minimize

drift, place the FP1 in a location that will not be subject to

rapid changes in temperature. Do not place near

exterior walls, AC or heating ducts, large appliances or

machinery.

Troubleshooting

Excessive Bounce and Drift in zero state (no pressure applied)

The FP1 sensors may act

erratically for several hours after being moved or repositioned. Allow time

for the sensors to settle.

Check pressure tubing

for moisture, condensation or water in the lines. Try replacing them.

Keep away from exterior

walls, heating and cooling ducts, large machines and appliances.

Do not place FP1 on a

surface that moves or vibrates.

Try relocating the FP1.

Wiring inside a wall or a large appliance or machine nearby may be creating

interference.

___________________________________________________________________________________

Sleep, waking up the FP1

It is important to use the sleep feature to prevent your battery from running down if you forget to turn off your FP1.

When the FP1 has not

received any input from the user or detected any pressure greater than .1”wc on PS1

(or

pressure greater than the value of p on later versions) for a duration

determined by the FP1 sleep timer

value (o), the FP1 will enter a sleep mode to

conserve battery life. The FP1 will report “Sleeping” when it

has entered sleep mode.

To

awaken FP1 form sleep mode, press any key on your keyboard

When the FP1 resumes

operation, it will zero the sensors and continue operation.

When the FP1 enters

sleep mode, FPcom will start a 5 minute timer. If the

FP1 is not awakened within 5

minutes, FPcom will turn off

the processor and display a message “Sleep Timer Expired”.

To

restart an expired sleep timer,

from the Fpcom menu select Processor | Proc On.

You can disable the

sleep feature on later model FP1’s by setting sleep timer (o) to zero. But if

you forget to turn off your FP1,

it will remain on

until your battery is dead.

___________________________________________________________________________________

FP1 to PC Connection

The FP1 connects to a

Windows 95 and later PC serial port. Serial ports are the D shaped plugs with 9

pins.

If you do not have a serial port, you should have a USB port. You can buy a USB to serial converter to run your FP1 from a USB port.

If using a USB serial adapter, make sure the adapter uses

the FTDI chip set. Read the instructions

that come with your adapter for installation.

Connect your FP1 Serial

I/O port to your computer serial port. Use the serial cable supplied with your

FP1.

If you do not have this

cable, you will need a F/F Null Modem 6’ cable.

You may use an extension

cable on your serial cable, but try not to exceed 10’.

If you have any trouble

with your FP1, try removing the extension cable.

When you start Fpcom, the FP1 should start sending text to the Fpcom document screen.

In the lower left hand

corner of your Fpcom screen, there is a small box

that reports your serial port connection with the FP1.

These are the messages

that will appear in this box, where # is the port number:

OFF The serial port is closed and the FP1

is off

ON# Fpcom was

able to open the # serial port

CK# Fpcom is

looking at the # serial port for the FP1 (FPcomXLV

only)

RC# Fpcom has

received data on the # serial port from the FP1

If FpcomXLV

is not able to find the FP1 on any serial ports, a message box will appear

showing you a report of the serial port search for the FP1.

You can also access this

report from the Processor | Serial Report menu item.

“Cannot

turn off your PC, disconnect your FP1 from the PC,

turn on your PC, when your PC finishes booting-up, reconnect the FP1 to the PC

serial port and try again.

If this solves the problem,

your PC is detecting the FP1 as a serial device, probably a serial mouse. If

you are good with computers,

you can go into Device Manager and find what it is

that your computer thinks the FP1 is (usually a serial mouse), and disable that

device.

ActiveSync, a program form Microsoft to communicate with

portable computers, can make connecting to the FP1 very difficult.

If you have ActiveSync on your computer, try disabling the serial

communications and reboot your computer.

___________________________________________________________________________________

FPcom Software

FPcom software operates your FP1 flow rate processor

from a PC. FPcom runs on Windows 95 and later powered

PC’s.

It is a text based

program that is very similar to a simple word processor like Note Pad.

There are several

versions of FPcom… FPcomXLS,

FPcomXLT and the latest version is FPcomXLV. All these versions can send

your FP1 data directly into an Excel spreadsheet in

real time as you flow test. FPcomXLV has enhanced

features for using a

velocity probe and Excel. See the section Excel for more information on using

Excel with FPcom.

FPcom makes it possible to do just about everything

using just a keyboard. This is because using a mouse in a shop

environment or on a flow bench is not always possible or

practical.

When you start FPcom, the program will try to find the FP1 on the

available serial ports of your computer.

When it has found the

FP1, the FP1 will start sending text data to the FPcom

document screen:

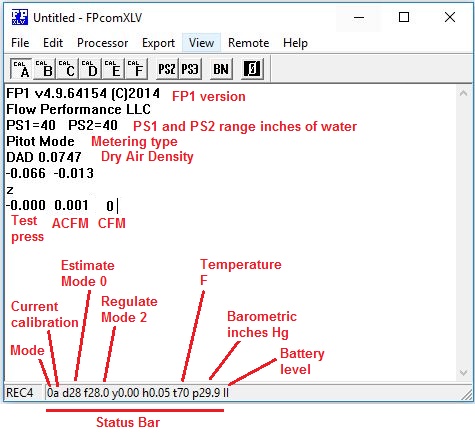

The status

bar is located at the bottom of the FPcom

document screen. It shows you important FP1 settings that will affect your flow

rate readings…

1A d28 f10 h.05 t70 b29.9

y0.0 III

1A < The number (1) is the current mode of operation. The

letter (A) is the currently selected calibration.

Upper case letter denote

Orifice bench is selected, lower case letter denote Pitot

bench selected.

d28 <

This shows the test pressure that the FP1 will estimate flow rates to

when in mode 0

f28 <

A center value for establishing a test pressure window for regulating

pressure Mode 2

h.05 <

This is used along with f to establish a test pressure window

t 70 <

This is the temperature entered by the user or by a temp sensor. Used to

calculate air density and

ACFM

p29.9 <

This is the barometric pressure entered by the user. Used to calculate

air density and ACFM

Note, p is used in the status bar, but

Barometric is accessed with the b command

Y0.0 <

this is a data reading damping value

III <

This is the battery level. III = good battery, I = weak battery, BAT

battery almost dead.

See the section FP1 Command List

for more details on the status bar values.

When you enter commands

to the FP1, they will be saved in the FP1, and will remain there even after you

turn off the FP1.

FPcomXLT and FPcomXLV features

a Big Numbers feature. Select menu item View | Big Numbers to enable this

feature.

You can drag the Big

Numbers window to any place on your screen with your mouse.

Data Capture There are several ways to capture

data.

Space bar data

capture will mark the current

line of data on the FPcom document screen with a

numerical value that is entered into Q,

then a new line of data is started and the value of Q

is incremented. If Q is set to 0.1, then the data on the FPcom

document will be

marked with each press of the space bar as shown below:

28.0

234.5 236.7 <Mark 0.1

28.0

234.8 237.0 <Mark 0.2

28.0

234.4 237.3 <Mark 0.3

The Mark value is reset

to Q each time the FP1 is zeroed.

If Excel is enabled, the

data is also sent to Excel with each press of the space bar and the row is

incremented with each capture.

Remote Mouse is featured on FPcomXLT

and FPcomXLV. Remote Mouse makes your mouse into a

remote data capture button.

A wireless mouse gives

you more freedom and perhaps range. It works just like the space bar except you

press the mouse left button to capture data.

Enable Remote Mouse by

selecting menu item Remote | Mouse. When Remote Mouse is enabled, a red box

will appear that will contain your mouse pointer.

Press the keyboard Esc

button to turn off Remote Mouse.

You turn off FPcom by clicking on the (X) icon in the upper right hand corner of the FPcom screen, or by selecting menu item File | Close.

When you quit FPcom, you will be asked “Save Changes to Document”.

This is asking you if you want to save the data that is on the screen as a text

file,

it has nothing to do with any changes you may have

made to your FP1 settings. If you do save your FPcom

document, add .txt to your file name

so that you can open your documents in other

applications like word processors or an Excel spreadsheet. Example: MyFlowTest.txt

If you do not want to

save your data on the FPcom document as a text file,

select NO.

See the section FP1 to

PC Connection for more information on connecting your FP1 to your PC and

information on serial ports.

See the section FP1 Commands and Data

Entry for information on controlling your FP1 through FPcom.

Note: if your FPcom software appears to freeze-up or become

non-responsive while entering commands,

see

your FPcom Help menu item “USB Connection”.

___________________________________________________________________________________

PS3 pressure sensor 3 (Optional)

FP1 version 3.17.32 and higher, supports a third pressure sensor in the FP1, pressure sensor 3, or PS3. PS3

can be used to measure flow velocities while flow volume rates are being measured on PS2.

PS3 is enabled by setting (a) to 1 (one).

PS3 is disabled by setting (a) to 0 (zero).

When PS3 is enabled, the data reading rate from the FP1 is slowed. This is because of the time required to

sample and process PS3.

If PS3 is disabled, make sure there is no pressure applied to all pressure sensors when enabling PS3. The

FP1 will enter the zeroing function when PS3 is enabled.

(v) is a trim multiple of the velocity reading. Be sure v is set to 1.0 if no adjustment is desired.

(V) determines velocity reading format. V = 1 feet per second. V = 0 feet per minute. Velocity readings in

feet per second are appended with an s (Example: 240s).

Mode 0 will estimate the velocity to the test pressure

entered into d.

Back

______________________________________________________________________________________

Velocity Probe

Click here to see velocity probe connection information.

A velocity probe can be

connected to the FP1 PS2 sensor. An optional pressure sensor

, PS3, can be installed into the FP1 for connection of a velocity probe.

While PS2 only gives you

the ability to read cfm from your flow bench or

velocity from your velocity probe, PS3 allows you to read cfm

from your

bench and velocity from your probe at the same time.

Velocity probe

correction can be entered in v

(lower case). Your velocity readings will be multiplied by the value of v. If

no correction is required,

or not known, set v to 1.0.

Feet/Second or

Feet/Minute is selected with V

(upper case). V = 0 (feet/minute). V = 1 (feet/sec). Velocity readings in

Feet/Sec will be appended with an s.

Mode 0 will estimate the velocity to the test pressure

entered into d.

Mode 1,2 and 4 will display the velocity relative to the actual

test pressure.

PS2

Connect impact port of probe to PS2+, and static port of probe to PS2-.

(If you get a test pressure reading and velocity reads zero when probe is inserted into an air stream, the probe is probably connected wrong).

Select calibration P. A fourth column of data should now appear on the FPcom document, velocity.

PS3

Make sure Calibration P, CAL P, is NOT selected.

Connect impact port of probe to P3+, and static port of probe to PS3-.

(If you get a test pressure reading and velocity reads zero when probe is inserted into an air stream, the probe is probably connected wrong).

Enable PS3 by setting a (lower case) to 1. Enabling PS3 will cause a forth column of data to appear on the FPcom document, which is velocity.

Enabling PS3 will slow down the FP1, so disable PS3 if not needed.

Not getting velocity

readings try reversing the

connection of the probe to the FP1.

If using PS2, make sure

calibration P is selected and a is set to 0 (zero).

If using PS3 make sure calibration

P is not selected, and that PS3 is enabled (a = 1).

_____________________________________________________________________________________

Excel

FPcom will

allow you to transfer the data from the FP1 flow processor directly into an

Excel (r) spreadsheet in real time as you flow test.

The

spreadsheet can be used to display the data, or to further process the data.

Make sure you are familiar with

your flow bench operation and using FPcom software

before attempting to use Excel.

Trying to use Excel when not

familiar with your flow bench and software can be a confusing and frustrating

experience.

The

spreadsheet that will receive data from Fpcom must be

named FPexcel.xls, and it must be located in the same location (drive, folder)

as FPcom.

You start

your Excel spreadsheet by selecting [Export | Excel] from the menu.

When you use a capture method

(Remote Mouse or keyboard space bar) the

data from FPcom will be sent to the top row of your

spreadsheet, starting at cell A1.

From the top row of the Excel sheet,

the data can be copied to other cells and further processed, in real time, as

the data is received by programming the Excel cells.

Error message: If you get error messages when Fpcom tries to launch your spreadsheet, from the Excel

program, open and then save your spreadsheet to

the folder

that FPcom is located. This will insure Excel knows where your spreadsheet is located.

Error message: If you

get a warning from Excel about macros within your spread sheet, you can set the

security settings for your

Excel program to a lower setting,

(only if you think your Excel sheet is safe).

You can

enable the arrow keys on your keyboard for velocity mapping (FPcomXLV)

by selecting menu item Export | VPExcel.

The default

starting cell for arrow key velocity mapping is A35.

Excel power users

Always

reserve the entire row 1 for receiving data from Fpcom. The amount of data sent to row 1

may increase in future releases of FPcom software.

Data will currently

go into your spreadsheet cells in this order by default:

A1 test pressure

B1 acfm

C1 cfm

D1 velocity

E1 mode

F1 calibration

C12 captured data start cell (z) Row will increment with each capture

I12 Captured data start cell (Z) Row will increment

with each capture

A35 Velocity mapping start cell. Row or

You can

reassign the cells that data will be sent to by creating a text file named FPconfig.txt (use Note

Pad) and locating it in the same folder as FPcom.

Include text in your FPconfig.txt file to indicate where

data should be placed. Below is a sample of the default settings:

R01C01

R01C02

R01C03

R01C04

R01C05

R01C06

R12C03

R12C09

R35C01

In the above sample, the first entry, R01C01 assigns the test pressure data to row 1 col. 1 (A1) and the last entry assigns velocity mapping start cell to A35.

If you do

not want a particular data item to be sent, use 00 for a row or column number,

that data item will not be received by your spreadsheet.

You can

check the assignments of your FPconfig.txt file by selecting the FPcom menu item [EXPORT | EXCEL CONFIG].

You can

make your spreadsheet launch automatically when FPcomXLV

is started by creating

a text file named excelon.txt (use Note Pad) and locating it in the same folder

as FPcom.

You can make

your spreadsheet appear on top of FPcom when started

by including the text EXCELONTOP in your excelon.txt file. Otherwise FPcom will remain on top of your spreadsheet.

You can

enable the keyboard arrow keys for velocity mapping on your spreadsheet by including the

text VPEXCEL in your excelon.txt file.

_________________________________________________________________________________

FP1 General information

The FP1 is not to be

used for measuring pressures of flammable gasses or gasses containing flammable

particles.

Warning:

The FP1 is not

intended for use in "

tool as well as a

measuring device. Because of this, the FP1 allows the user to configure and

adjust many

settings and parameters

of the FP1. While every attempt is made to check the user settings and

parameters

for valid entries, it is

not possible to anticipate every possible combination for validity of data

input by the

user. The user is

responsible for checking the validity of all data parameters and that the

processor is

functioning properly at

all times.

Flow Rate Detection

The FP1 is designed to

process the differential pressure obtained from pressure differential producing

flow

measuring devices,

specifically, Pitot tube type velocity measuring

devices or a measuring orifice.

PS2 (pressure sensor

2) is used to measure the actual

differential pressure from the differential pressures.

PS1 (pressure sensor

1) is used as a reference

pressure port for measuring test pressures and calculating

standard flow rates. It

is also used as a trigger for some modes of operation. For instance, in modes 0

- 2,

the user can set a

threshold pressure on PS1 to scroll the FP1 readings down the display screen

when that

pressure is met or

exceeded. The FP1 also monitors PS1 for pressures greater than .1”wc to trigger

other

activities, such as

resetting the FP1 processor sleep timer.

Optional PS3

(pressure sensor 3) is for use

as a dedicated velocity probe sensor. You can use a velocity probe on PS2, but

you will not be able to get your

cfm readings

from your flow bench. Using PS3 for a velocity probe allows you to get your

flow bench cfm and your velocity probe readings at

the same time.

Pressure sensors PS1

and PS2, (and optional PS3)

Maximum allowed applied

pressure is 11psi (about 300”wc).

Negative pressures

should not be applied to the positive pressure ports.

Positive pressures

should not be applied to the negative pressure ports.

Pressure readings are

always displayed as a positive value, even when a negative pressure is applied to the negative pressure port.

Modes of Operation

The FP1 has 5 modes of

operation. Modes 0 - 2 are flow rate calculating .

See the section “FP1

Command List” “m” for more information

on mode, or click here for more information on mode.

Power Requirements

The FP1 uses a 9 volt

battery for power. This battery should be an alkaline type for about 25 to 35

hours of

normal use (depending on

installed options and modes of operation). A Ni-Mh

rechargeable battery is recommended for “Power Users”.

The FP1 has a user

programmable sleep mode that will help prolong battery life and prevent the

battery from exhausting if the user forgets to turn off the FP1.

The sleep timer value (o)

has a range between 1 and 255 seconds.

___________________________________________________________________________________

For connection diagrams, see your FPcom Help menu item “Setup Configurations”.

Click here to

see setup configurations

The FP1 PS1 connects to

your receptacle or settling chamber test pressure port.

PS2 connects to your

flow measuring device impact and discharge or static port.

The impact port is the

port that is on the side that air will be entering, or impacting, while the

discharge port is the side of the device that the air will be discharged.

In bi-directional

applications, the impact and discharge ports change with the direction of the

airflow.

Use these conventions

below in determining how to connect your orifice bench to the FP1.

Flow Performance System Connections

(FP2.0BS, FP2.5BS)

Click here for setup information

The FP1 PS1 connects to your bench receptacle, and PS2 connects to your

flow element.

For forward flow (Vacuum

applied to bench) connect the FP1 in the following way:

PS1- to receptacle

PS1 + unconnected (open)

PS2+ to flow element + port

PS2- to flow element – port

For reverse flow (+

pressure applied to bench) connect the FP1 in the following way:

PS1+ to receptacle

PS1 – unconnected (open)

PS2+ to flow element – port

PS2 - to flow element + port

Orifice and other flow element Connections

For forward flow (Vacuum

applied to bench) connect the FP1 in the following way:

PS1- to receptacle or settling chamber

PS1 + unconnected (open)

PS2+ to flow element or orifice impact side

PS2- to flow element or orifice discharge side

*Center blower benches:

PS2 + connects to orifice chamber

PS2 - open

For reverse flow (+

pressure applied to bench) connect the FP1 in the following way:

PS1+ to receptacle or settling chamber

PS1 – unconnected (open)

PS2+ to flow element or orifice discharge side

PS2- to flow element or orifice + impact side

*Center blower benches:

PS2 - connects to measuring orifice chamber

PS2 + open

If you

get a test pressure reading, and your cfm reads zero PS2 is probably connected backwards.

________________________________________________________________________________

Flow Bench Operation

The following is general testing procedures used when testing

internal combustion engine over head valve cylinder heads.

It may include or omit some procedures that may be important

to your specific testing requirements. Your testing specifications may differ.

Preparation

Always wear approved eye protection when

operating your flow bench.

Always keep your

bench area clear of any objects or substances that could fall into the

receptacle.

Never look into the

receptacle while air pressure is being applied.

Disable the air

source before inspecting the inside of the receptacle.

Always check the

receptacle for objects or substances that may have fallen into the receptacle

before applying air

pressure.

Always do your

exhaust port testing first, and quickly, while your air source air is cool.

It is important to check

your equipment before doing any flow testing to ensure everything is working

correctly. The easiest

way to do this is to flow test a calibration orifice for proper flow rates, and

to make

any minor adjustments to

calibration before testing.

The most common reason

for errors in flow testing are caused by air leaks. Since the FE series flow

elements are not capable

of measuring air flow down to zero, no reliable method of leak testing is known

at

this time. It is up to

the operator to ensure that air leaks are not occurring.

When starting the FP1

flow processor, it will take a minute or two for the pressure sensors to settle

down

before they can be zeroed properly. Sometimes they will

loose their zero state after having pressure

applied. For this

reason, it is always a good idea to flow a calibration orifice and re-zero the

FP1 before

doing any flow testing.

Connect the FP1 to

your bench in the proper fashion

(see Flow Bench Connections for more info)

Set your FP1 for the correct

calibration and mode. Flow

Performance systems typically use cal A for forward flow, and cal B for reverse

flow.

If you are not

regulating your test pressure you will probably want mode 0 (zer0), otherwise

mode 1 or 2 should be used.

Check the FPcom status bar to make sure you are in the correct mode

and that all your parameters are appropriate for your flow test.

Zero the FP1 before

doing any testing

Test Piece

Preparation

The most common way of

mounting a test piece to the receptacle is by using C clamps or similar

clamping

devices. Do not over

tighten the clamps. Just snug them down. Over-tightening the clamps may

distort

the surface that the

receptacle is mounted to, causing air leaks or damage.

Make sure your test piece

is mounted with an even clamping force and not cocked or skewed.

Check the receptacle

gasket for bits of debris or for bumps or an uneven surface before mounting the

test

piece.

Make sure the sealing

surfaces are clean and smooth. If you need to use grease on the rubber gasket,

use

only a water based jell.

Oil based grease will destroy the rubber gasket.

On cylinder heads, apply

grease to both valve stems, the valve seat of the valve that will not be flow

tested

and to the threads of

the spark plug or the plug that will seal the spark plug hole. This will help

ensure these

areas will not leak air.

Prepare your test piece

before mounting the head on your bench. Installing your valve depression device

and any clay radiuses

onto your test piece is usually much easier before mounting the piece.

Zero the FP1 before

doing any testing

Always wear eye

protection when operating your flow bench.

Always use vacuum to flow test an item if possible. Use

positive pressure only if using vacuum is not practical.

Positive pressure sources often create rapidly changing

air temperature and initial velocity.

Because most air sources heat the air that they

supply, it is important to follow some

special procedures when testing in the exhaust mode.

It is important to do

your exhaust flow testing

first, and quickly.

By testing your exhaust

port before the intake port, your air source motor will not yet be hot and will

not

heat the air too much.

Don’t let the air source

run while not testing. The longer your air source runs, the hotter the air will

become. Only run the air

source while actually testing, then turn it off if more exhaust testing is

expected.

Mounting the test piece

for exhaust testing most be done very carefully because the air pressure will try

to

push pieces apart, where

vacuum pressure tends to pull them together. Also, as the air heats things,

things

tend to change.

An extension to the

exhaust port will dramatically affect your readings. Any change you make to the

extension, diameter,

length, position, curvature and direction of any curvature will affect your

flow

readings. If using an extension, be sure to document it in detail for others to duplicate your test. Also include flow data not using the extension.

Zero the FP1 before doing

any testing

It is important to do

exhaust port testing first. This is because most air sources heat the air in

exhaust mode

and the exhaust should

be tested before the air source exhaust air becomes too hot.

Make sure you have installed

a radius to the port entrance before mounting your test piece. You can use clay

or plumbers putty to make a radius,

but most children’s clay has a lot of corrosive

properties, do not leave on your test piece.

Plumbers putty is oil

based and should not corrode your test piece if left on.

Adjust your air source

to create a negative air pressure (vacuum).

_____________________________________________________________________________________

Flow Bench Calibration

The FP1 has provisions for 6 calibrations. These calibrations are assigned letters A, B, C, D, E and F.

Flow Performance flow bench systems usually use Cal A for forward flow, and Cal B for reverse flow calibrations.

Calibrations are selected with the M command, and starting with FPcomXLV, by selecting the calibration from the Fpcom tool bar or by using

the Ctrl key and calibration letter.

The selected calibration is displayed as the first set of data on the Fpcom status bar along with the mode. Example: 1A shows mode 1, Cal A is selected.

For Pitot benches (FP2.0BS, FP2.5BS) a separate calibration can be made for forward and reverse flow.

For orifice benches, 6 orifices can be calibrated, or for more accuracy, 3 orifices can be calibrated in both directions of flow.

For Pitot benches (FP2.0BS, FP2.5BS) the area of the flow element, in square feet , is entered into the calibration,.

Then this figure is adjusted to obtain the correct calibration while flow testing a calibration orifice.

For instance, a 2” flow element has an area of .0218 square feet. To enter a calibration into calibration A:

A [RETURN] .0218 [RETURN]

Adjust this value to calibrate your system.

If your cfm readings are too high, use a lower value. Example, try .0217

If your cfm readings are too low, increase the value. Example, try .0219

For orifice benches, the diameter of the orifice, in inches, is entered into the calibration. Each calibration has an associated Cd, which is stored in G through L.

The orifice Cd is adjusted to obtain the correct flow reading while flow testing a calibration orifice. A typical Cd for a sharp edge orifice is .62, and this is

a good Cd to start with when calibrating an orifice.

Orifice Cd

-----------------

A G

B H

C I

D J

E K

F L

For instance, to set up a calibration (A) for a 2.123” diameter orifice:

A [RETURN] 2.123 [RETURN]

Then enter a Cd for calibration A:

G [RETURN] .62 [RETURN]

Now, you may want to set up a calibration for the reverse direction flow through that orifice (A) in calibration B. You do this the same way you used to set calibration A.

B [RETURN] 2.123 [RETURN]

Then enter a Cd for calibration B:

H [RETURN] .62 [RETURN]

Sharp edge calibration orifices, like the ones from Flow Performance, are used so that air enters the sharp edge side, not the beveled side.

Some FP calibration orifices are square edged, with no bevel. They can be used either direction, but for best results,

t is suggested that air enter the side that the flow data is written.

Multiple orifice benches:

Orifice benches, which use multiple orifices, simultaneously (not to be confused with multiple ranges), you need to calculate a total diameter of all open orifices.

To do this, you need to calculate the area of each orifice, then determine the diameter of the sum total area:

Area of an orifice = 3.1416*(Diameter*Diameter)/4

Diameter of a round area = SQRT((Area/3.1416))*2

System-On Calibration

System-on

calibration allows you to make small adjustments to the currently selected

calibration (

Normally, you would be flow testing an object with a known flow rate such as a calibration orifice while

Performing a System-On calibration.

Using the lower case c command, the currently selected

calibration (

When attempting to match the FP1 readings to a known flow rate:

Turn on you flow bench with calibration item mounted, and obtain the desired test pressure if needed.

· Press c and then RETURN. The FP1 will take a flow rate measurement and display the CFM.

· Press the + key or - key then RETURN to increment or decrement the Calibration factor, the FP1 will repeat the flow rate measurement and display the new CFM.

· Press RETURN when the FP1 flow rate measurement is satisfactory.

PWM Port

The Aux3 PWM

port is used to operate a PWM (Pulse Width Modulated) valve to regulate test

pressure automatically.

The PWM port

is only activated in mode 2.

The FP1 will

adjust the PWM signal in response to the test pressure readings it receives

from PS1, to try to obtain the test pressure value entered into f..

Since it is

virtually impossible to achieve the exact test pressure entered into f

to within .001”wc, a tolerance has to be established,

and that is done with the value entered into h.

If f

is set to 28 and h is set to .05, then the test pressure is considered

“achieved” when the pressure is between 27.95 and 28.05”wc (f +/- h).

To test the

Aux3 PWM port and your PWM valve, set the FP1 mode to any mode except mode 2.

Change the value

of P (upper case) from 1 to 0, and 0 to 1. The PWM valve should fully open and

close when these values are changed (if properly adjusted).

When you

select mode 2, the valve should open half way, or to the value entered into O

(upper case).

When you

leave mode 2, the valve should close. If not, change the value of P to 1 or 0.

Valve

won’t move Check

that the cable is fully inserted into each jack. Try a new battery. If using an

extension cord, try without extension cord.

Test

Pressure gets to a certain point, then no change It may be that the valve is not able

to bleed off enough pressure from your system (intake testing),

or your

system is not able to produce enough pressure (exhaust testing). If intake

testing and valve is fully open, it can’t bleed off enough pressure.

If exhaust

testing and valve is fully closed, your system is not able to produce the

desired test pressure.

Test

pressure swings over and under desired test pressure try increasing the value of h.

_________________________________________

Parameters and commands for FP1 version 3.41.64 and higher

a Enable PS3, a=1 enable, a=0 disable A Calibration A value

b Barometric pressure B Calibration B Value

c calibration value for current calibration C Calibration B Value

d Estimate test pressure, mode 0 D Calibration D value

e Flow device, 1=Pitot, 0=Orifice E Calibration E Value

f Test pressure target F Calibration F Value

g

h

i Calibration P calibration I Orifice C Cd, or Pitot D comp

j PWM port (Aux3) step high J Orifice D Cd, or Pitot D comp

k PWM port (Aux3) step medium K Orifice E Cd, or Pitot F comp

l PWM port (Aux3) step low L Orifice F Cd, or Pitot F comp

m Mode. 0,1,2,3,4 M Calibration. Select Calibration

0 estimate flow to d Example: M [RETURN] A [RETURN]

1 flow propotional to test press or Ctrl A

2 Same as 1 with PWM enabled

3 Manometer

4 Velocity probe graph

n PWM port (Aux3)

limit

o Sleep timer seconds. 254 max. 0=no sleep O PWM port start position (1600 for FV3)

p Minimum pressure before calculate flow P PWM port stop position (1 for FV3)

q PWM port (Aux3) window medium

r Reset FP1

s Sample duration, 1 to 50 S Mode 2 sample duration

t Temp for acfm

u Data update delay 1 - 254

v Velocity probe correction V Velocity format, 1=FPS 0=FPM

w Display Weather entries and sensors W Cycles for important updates (100)

x PWM port (Aux3) limit

y Damping value in cfm

z Zero FP1. Not while bench on! Z Hard zero, will zero FP1 no matter what

Important Default settings: o=254 p=.1 s=50 u=1 y=0

FP1 version 3.58.64 and later....

~ Restore FP1 parameters to factory settings

R Report all parameters

______________________________________________________________________________________

FP1 Entering Commands and Data

The user can enter data

parameters and settings to the FP1. The user can also enter commands to invoke

a response or retrieve parameters from the FP1.

Commands are case

sensitive!

Note: if your FPcom software appears to freeze-up or become

non-responsive while entering commands,

see

your FPcom Help menu item “USB Connection”.

Commands and data are

entered through the keyboard on your controlling computer.

Data or commands are

entered in the following way:

Press a keyboard key,

then press RETURN or ENTER.

The current value for

the entered command or data will be displayed, and “Enter New Value” will also

be

displayed.

Enter the new value,

then touch the RETURN or ENTER key to enter the data or command.

The FP1 should now

continue to display pressure sensor readings.

If you enter the wrong letter, don’t use the backspace, just enter the correct command letter.

The FP1 accepts only the last letter entered as the command. For instance, if you enter this as a command: abcd

The FP1 will accept d as the command. a, b, and c are ignored.

If you just want to

see what the value for your

entry is, but don’t want to change it, simply press

RETURN or ENTER after

the value has been displayed. The value will not be changed.

The FP1 will report “?”

if you entered a command that it does not recognize.

Note:

When entering a data value of 0 (zero), do not enter 0.0 Only enter 0. The FP1

software does not accept

a value of 0.0.

Critical

Data

Critical data is data

that is set at manufacture and should not be changed unless authorized by a

technician.

Changing critical data

will result in incorrect operation of the FP1. If you invoke a command that has

critical data, you will

be asked “Critical Data! Are you sure? YN”. Press N to indicate “No”.

You will be

returned to normal

operation.

___________________________________________________________________________________

Commands and Data Listing

Commands are case

sensitive! (LC) Lower Case (UC) Upper Case

a (LC)

Version 3.19.32 and later. Enables a third pressure sensor, PS3. 1 = PS1

enabled, 0 = disabled

A (UC)

Assignment for Pitot calibration or orifice diameter.

See M for more information.

b (LC)

Barometric pressure. User input. Units are inches of mercury (inHg) referenced to sea level.

Used to calculate Dry Air Density and Actual CFM

(ACFM).

B (UC)

Assignment for Pitot calibration or orifice diameter.

See M for more information.

c (LC)

Versions 3.15.32 and earlier Calibration Pitot

tube. User input. Used to calculate cfm for a Pitot

tube. This value should be approximately the area of the cross section of

the conduit in which the flow is

being measured, in square feet.

Version 3.16.32 and later

c is used for the

system-on calibration feature. See the document on System-On Calibration for

more info. While flow testing a known flow rate, entering c enables

the system on calibration

feature. The + and - keys can be used to bump the current calibration

factor up or down for the

selected device.

e = 1 Pitot tube devices are selected. The Calibration

factor for the currently selected

calibration is bumped up or down by the + or - keys.

e = 0 (zero) Orifice

devices are selected. The Cd value for the currently

selected orifice,

A - F, is bumped up or

down by the + or - keys.

C (UC)

Assignment for Pitot calibration or orifice diameter.

See M for more information.

d (LC)

Depression Conversion Value (DCV). User input. This value is used to compute

the equivalent

rate of flow to a depression other than the actual depression. For

instance, if a measurement is made at

16”wc and the DCV is set to 28, the cfm reading

will reflect what the cfm would be if the depression

were

actually 28”wc.

D (UC)

Assignment for Pitot calibration or orifice diameter.

See M for more information.

e (LC)

Measuring device type. (Version 3.16.32 and later) User input.

Determines which type of

measuring device is being used for Flow Mode calibration factors A -

F.

e = 1 (one) Pitot tube devices. A - F can be set to calibration

factors for Pitot tubes. These

calibration factors are generally area in square feet of the bounded path

that the Pitot tube is

located.

e = 0 (zero) Orifices

devices. A - F can be set to the diameter of the orifices, in inches. G

- L can

be set to the orifice Cd rates for orifices A

- F respectfully

E (UC)

Assignment for Pitot calibration or orifice diameter.

See M for more information.

f (LC)

Depression Threshold Value (DTV). User input. This value determines when

measurement

readings will be scrolled onto the display screen as a result of the

pressure applied to PS1. For instance, if

the DTV is 10”wc, the measurement readings will be scrolled onto the

display screen when the pressure

applied to PS1 equals or exceeds 10”wc.

F (UC)

Assignment for Pitot calibration or orifice diameter.

See M for more information.

g (LC)

Servo Window High Value. User Input. The higher pressure reading that the FP1

should seek

using the Servo Step High Value (j)

G (UC)

Assignment for orifice A Cd or Pitot

B comp factor. See M for more information.

h (LC)

Hysterisis. User input. (Must be in Mode 2) This

value establishes a pressure window on PS1

using f, the DTV, as the window center. Whenever the pressure

applied to PS1 falls within the window, the

measurement readings are scrolled down the display. For instance, if f

is 10’wc, and h is 0.05, then the

window is 9.95 to 10.05”wc. Whenever the pressure applied to PS1 falls

within this window, the

measurement readings will be scrolled down the display screen.

H (UC)

Assignment for orifice B Cd or Pitot

B comp factor. See M for more information.

i (LC) Pitot tube

calibration factor. (Version 3.16.32 and later) Approximately the area

of the bounded

path that the Pitot tube is located, in square

feet. Even if e is set to orifice devices, if the Flow Mode is set

to P, the user can use a Pitot tube

device or velocity probe. i allows the

user to supply the area being

measured to calculate volume of flow.

I (UC)

Assignment for orifice C Cd or Pitot

D comp factor. . See M for more information.

j (LC)

Servo Step High Value. User Input. The servo position value is stepped by this

value. This is the

servo high speed value, and is used while the FP1 is finding the servo

window High Value g.

J (UC)

Assignment for orifice D Cd or Pitot

D comp factor. See M for more information.

k (LC)

Servo Step Medium Value. User Input. The servo position value is stepped by

this value. This is

the servo high speed value, and is used while the FP1 is finding the

servo window medium Value q.

K (UC)

Assignment for orifice E Cd or Pitot

F comp factor. See M for more information.

l (LC)

Servo Step Low Value. User Input. The servo position value is stepped by this

value. This is the

servo low speed value, and is used while the FP1 is finding the Hysterisis window value (h).

L (UC)

Assignment for orifice F Cd or Pitot

F comp factor. See M for more information.

m (LC) Mode of operation. User Command. Mode

determines how data is displayed.

Mode 0 The cfm values are converted to the equivalent cfm values of the Depression Conversion

Value (d).

Mode 1 The cfm are the real cfm values and

are not converted to the Depression Conversion

Value (d).

Mode 2 Pressure Sensor 1

window mode.

applied to PS1 fall within the pressure window established by f and

h. FP1 Standard servo port is

activated in mode 2.

Mode 3 Manometer mode. PS1

and PS2 are in manometer only operation, displaying inches of water..

Mode 4 Velocity graphing mode.

A simple text velocity graph displays velocity. Velocity readings are displayed

in the status bar.

M (UC) Versions 3.0.32 through 3.15.32. Flow measurement mode. User input.

Allows 6 calibrations for orifice systems. Calibrations are indicated as A,

B, C, D, E, F and P. Flow mode

is displayed in the Fpcom status bar next to

the mode of operation.

Example: 1A Mode 1, Calibration A is selected

Example: 0B Mode 0, Calibration B is selected

P Pitot tube system or velocity probe. A Pitot tube or velocity probe is used to measure flow rates.

The calibration value for the Pitot tube is

stored in command c (see command c for more

information). P can be selected while in either orifice or Pitot mode

A - F Orifice is used to

measure flow rate. 6 different sized orifices sizes can be entered (A - F)

for instant recall and use. Sizes entered should be in inches diameter.

G - L Orifice coefficient

of discharge value A - F respectfully. The default Cd

is .62

If the CD of the orifice is not known, this value can be adjusted while

flow testing a

calibration orifice to determine the proper Cd.

Versions 3.16.32 and later.

A - F can now be used to

store orifice diameters or Pitot tube calibrations.

The e command is used to

determine which type devices (Pitot of orifice)

are being used (See command e for more information).

M can also be set to P to

use a Pitot tube device (velocity probe) even if

orifices are the current mode of

measurement (e = 0).

P Pitot tube or Pitot tube

velocity probe device. Even if e has been set to orifice, the user can

use a

Pitot tube device or velocity probe when the Flow Mode is set to P. A

calibration value for the

Pitot device is stored in i (See

command i for more information).

A - F Calibrations for

flow measuring device. 6 calibrations are allowed. The user enters the

calibration factor for the device selected (Pitot

or orifice)

Pitot Tube

Applications (FP2.0BS, FP2.5BS)

If e =

1 Pitot tube device is selected. A - F are set

to the approximate area of the

bounded path that the Pitot tube is located

(square feet). The flow mode is displayed in

the status bar as a small letter:

Example: 1a shows mode 1, Pitot

calibration a selected.

Example: 2c shows mode 2, Pitot

calibration c selected

Version 3.19.32 and later

Calibrations B, D and F can have compensation factors for

non-linear

measurements. If no compensation is desired, comp values must be 0

(zero).

B compensation factors are

located in G and H

D compensation factors are

located in I and J

F compensation factors are

located in K and L

Contact Flow Performance for info on compensation factors for non-linear

measurements.

M Versions

3.16.32 and later. continued…

Orifice Applications

If e = 0 (zero) Orifice measuring devices are selected. A - F are

assigned to orifice

diameters in inches. The flow mode is displayed in the status bar with an

upper case

letter.

Example: 1A shows mode 1, Orifice A selected

Example: 2C shows mode 2, Orifice C selected

G - L Orifice coefficient

of discharge value A - F respectfully. The default Cd

.62

If the CD of the orifice is not known, this value can be adjusted while

flow

testing a calibration orifice to determine the proper Cd.

n (LC)

Servo Minimum Position. User input. The minimum position setting for the servo

port (AUX 3).

The FP1 will not allow a servo position value greater than the Servo

Maximum.

N (UC)

Servo Mode. User input. This value reverses the operation of a servo motor.

Generally, when

controlling a bleed valve, you want the valve fully open when not in operation, and

to

close to obtain the correct air pressure. This value will orient the

servo operation correctly depending on

how you have your servo positioned or mechanically connected to the

valve. Values are either 0 or 1.

o (LC)

Sleep timer. User input. Amount of time, in seconds, that will elapse before

the processor will put

itself into a sleep mode if one of two things do not occur in that time

frame: 1, no user input to the

processor. 2, no pressure applied to PS1. Values 1 to 255. This is to

preserve battery life. NOTE: If the

battery level indicates BAT, the processor will turn itself off when

entering into sleep mode. This

is

because the processor will not be able to detect a dead battery condition

while sleeping.

O (UC) Servo Start. User input. Version 3.5.32 and

later

This determines the default position the servo will assume when mode 2 is

enabled. In earlier FP1 versions,

a value of 1 will position the servo to Servo Max, while a value of 0

will cause the servo to assume the

position of Servo Min.

Newer FP1 versions (3.15.32 and later) allows O to be set to any value between Servo Max and Servo Min.

This allows the servo to rest at other positions other than Max and Min.

This can help shorten search times

by starting the servo position half way between Max and Min. Values

entered above Max or below Min

will be saved as Max or Min.

If Servo Start is set to 0 (zero) or a value less than Servo Min, the

servo will assume the Servo Min

position. If Servo Start is greater than Servo Max, the servo will assume

the Servo Max position.

If Servo Start is between Servo Min and Servo Max, the servo will assume

the position of Servo Start.

p (LC)

Test Pressure Minimum value. Version 3.3.32 and later. This value sets the

minimum pressure on

PS1 to calculate flow rates by the processor. Values are in inches of

water column. A value of .100”wc will

indicate to the processor to calculate flow rates only when the pressure

on PS1 exceeds .100”wc. When

pressure on PS1 is less than .100”wc, the processor goes into manometer

mode to display the zero state of

the pressure sensors. This does not apply to mode 3, manometer mode.

P (UC)

Servo Stop. User input. Version 3.5.32 and later

This determines the position the servo will assume when not in mode 2. If

Servo Stop is set to 1, the servo

will assume the position of Servo Max, while a value of 0 will cause the

servo to assume the position of

Servo Min.

q (LC)

Servo Window Medium Value. User Input. The medium pressure reading that the FP1

should

seek using the Servo Step medium Value (k)

r (LC)

Reset. User Command. Causes a software reset of the FP1 processor. Use reset if

the FP1

processor appears to not be working correctly.

s (LC)

Sample Duration. User input. Values 1 to 50. The sample duration taken on each

pressure sensor

for a reading. More duration takes more time to process but result in

smoother readings. Less duration takes

less time but result in less stable readings.

S (UC)

Sample duration mode 2 only. User input. Range 1 to 50. 1 is the minimum

pressure sample

duration while 50 is the longest duration.

t (LC)

Temperature. User input. Units are degrees Fahrenheit. Ambient temperature used

to compute the DAD (Dry Air Density) and

the ACFM (Actual CFM).

u (LC) Update delay. User input. Values 1 to 255.

The amount of delay between sensor sampling and

display cycles. About 10mS (.1 seconds) per unit. Slower computers may

need longer delays. Longer

delays may also be needed with FPcomXL on

slower computers.

v (LC) Velocity Probe Compensation. A velocity probw will usually have a compensation value.

Flow Performance S-type velocity probes have a compensation value of

about .83.

If your probe did not include a compensation value (sometimes referred to

as a correction value),

Then enter 1.0

V (UC)

Velocity Probe reading format. User input. FP1 software

version 3.1.32 and later. Determines

how the velocity reading will be formatted on your display. If V is

set to 0 (zero) the velocity reading will

be displayed as Feet per Minute. If V is set to 1 (one), the

velocity reading will be displayed as Feet per

Second. The Feet per Second reading will have an s notation to indicate

that the reading is in Feet/Seconds.

Example: 456s

FP1 models with software versions before 3.1.32 only display velocity in

Feet per Minute

x (LC) Servo Maximum Position. User Input. The

maximum position setting for the servo port (AUX 3).

The FP1 will not allow a servo position value greater than the Servo

Maximum.

y (LC)

Damping Value. User Input. This value determines how much the cfm reading must change before

the reading is actually reported as a new value. For instance, if the Damping

value is 1.0 the cfm reading

must be at least 1 cfm higher or lower than the

previous reading to change the reading. Otherwise, the cfm

reading remains the same. This helps steady readings of turbulent air

flow or pressure fluctuations.

z (LC)

Zero pressure sensors. This causes the FP1 to zero the pressure sensors. There

should be no

pressure applied to the pressure sensors while zeroing, and the tubing

connecting the FP1 to the flow

measuring device should not be moved. If there is pressure applied to the

pressure sensors above the value

determined by p, the minimum pressure value when z is entered,

then the FP1 will enter System-On

calibration mode for Pitot tube type flow

devices.

Z (UC)

Hard zeroing. Version 3.6.32 and later. Hard zeroing causes the FP1 to zero the

pressure sensors

no matter what the minimum pressure value, p, is set for. This

allows zeroing of the pressure sensors even

while the minimum pressure value, p, is set to very low values.

; Edit.

Pressing the ; key stops the FP1 from sending any further data and gives the

user control of the

Fpcom text editing. The user has about 90 seconds to enter a text character,

and about 60 seconds after each

character entered before Fpcom will allow the

FP1 to begin transmitting data again.

The user can exit the edit mode by pressing ; allowing the FP1 to resume

data transmission.

This gives the user an opportunity to enter notes and comments to the FP1

readings.